The HV DryShield® line of CTs has been designed for a very long component and operating life. To achieve this the design looks at achieving optimum performance in three specific areas:

- A Low Dielectric Loss for the Main Insulation Material

- Small Partial Discharge Levels

- A Low Uniform Electric Field

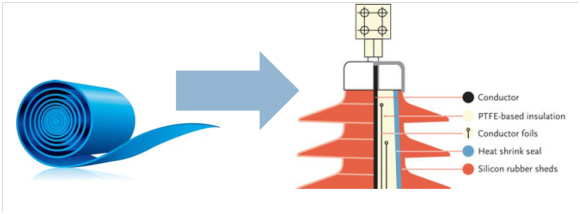

The tanδ of the insulation material is very important to the design. Too high a tanδ will cause the insulation material to overheat which can lead to thermal instability and even breakdown. The main insulation material used in the HV DryShield® CT is PTFE tape and interstitial silicone gel. PTFE is an excellent electrical insulation material. It has excellent temperature stability (-260C to +260C). It is a nonpolar material, with extremely low dielectric dissipation factor (tanδ) (1*10-4) and high physical and chemical stability characteristics. The result is a CT that has a very low and steady tanδ (typically in the range of 0.04%). Such a consistently low tanδ ensures a very slow deterioration rate of the main insulation material.

The reason for the use of silicone gel with the PTFE tape is to fill in the micro gaps, and expel the air bubbles in the insulation tape, leading to very low levels of Partial Discharge (PD). This protection from electric corona does not deteriorate over time as silicone gel has a high stability against ionizing making it less likely to age. Production test PD values for HV DryShield® CTs are ≤ 5 pC.

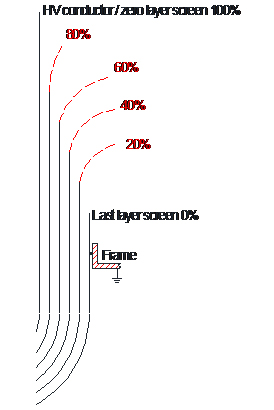

A finely graded condenser design allows both the inner insulation and outer insulation to operate under a lower electrical field stress.

Potential distribution in cylindrical condenser

By adjusting the number and length of metal foil screens, as well as the layer thickness between the screens, the voltage drop and also electrical stress in the core and along its’ surface can be controlled. This ensures a uniform electric field along the surface of the outer insulation increasing the flashover voltage withstand along the surface and helping to limit the deterioration rate of the silicone rubber.

In summary, the combined effect of a finely graded condenser structure and a PTFE tape and interstitial silicone gel insulation system results in a CT design with extremely low PD levels (≤ 5 pC), small tanδ values (in the area of 0.04%), high withstand voltage levels and superior aging resistance properties.

RHM International's lines of HV Dryshield Current Transformers