THE FIRST BUSHING INTEGRATED COMBINED LPIT INSTRUMENT TRANSFORMER.

OUR NEW BIIT™ HV MEASUREMENT BUSHING FOR YOUR DIGITAL EQUIPMENT APPLICATIONS

The BIIT™ Bushing with its integrated combined Low Power Current and Voltage Transformer (LPIT) is the fundamental component for our unique line of digital substation products that include miniaturized GIS and combined instrument transformers.

- BUILT-IN CAPACITIVE VOLTAGE DIVIDER AND ROGOWSKI COIL CIRCUITS PROVIDE VOLTAGE AND CURRENT SIGNALS

- CIRCUITS ARE INTEGRATED INTO THE TYPE TEST VALIDATED, EXPLOSION – RESISTANT AND ANTI-SEISMIC RIF® BUSHING. THE DRY TYPE RIF® TECHNOLOGY IS PAPERLESS AND ASSURE A FULL RESISTANCE TO HUMIDITY

- NO ELECTRONIC COMPONENTS AT THE HIGH VOLTAGE END

- PROVIDED WITH ONE SUPPLY AND ONE BACKUP SIGNAL COLLECTOR THAT CAN BE INSTALLED AT GROUND LEVEL ON THE SUPPORT COLUMN OF THE OPERATING EQUIPMENT FOR SIGNAL RELIABILITY AND CONVENIENT MAINTENANCE

- A MAINTENANCE-FREE BUSHING THAT HAS BEEN TESTED FOR ALL EXTREME ENVIRONMENTAL OPERATING CONDITIONS

- ONLINE PARTIAL DISCHARGE MONITORING OF THE OPERATING EQUIPMENT.

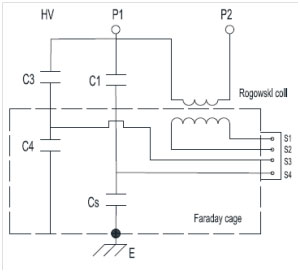

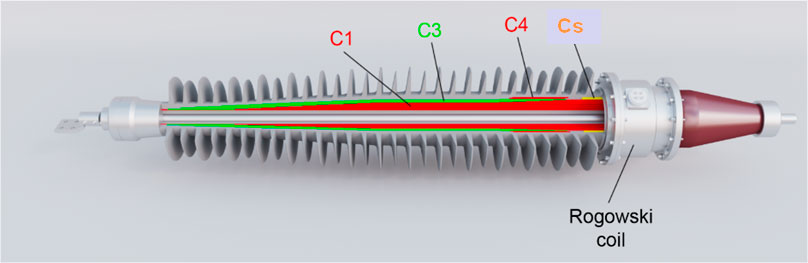

The Integrated Measurement (LPIT) Technology

Cs – low-voltage capacitor that extracts the voltage signal

C3 – anti-interference capacitor

C4 – information collection capacitor

The electronic voltage transformer function is realized by measuring the terminal voltage on Cs.

The electronic current transformer function is realized by using the principle of Faraday electromagnetic induction with several large air-core coils installed inside the grounded flange and outside the grounding screen.

Online partial discharge monitoring is realized using RHM’s patented monitoring technology that uses C4 to collect pulse current signals.

Applications for this Technology

The new HV measurement bushing with integrated LPIT has allowed RHM International to develop unique types of digitalized equipment for substations, some examples of which are:

How can we help you in your digital development? Contact us.