Most utilities still maintain a large inventory of legacy (40+ years) transformers that are still in-service with their original supplied OIP bushings. Because of the standards and generous margins used in the design and construction of these older transformers, these transformers continue to provide reliable service. However, it is well known that over time dielectric deterioration, aging and overvoltage and thermal stresses can affect the reliability of OIP bushings. In many cases this has led to the catastrophic failure of the OIP bushing, jeopardizing personnel safety and the operational reliability of the transformer asset.

The RIF® bushing technology and its manufacturing processes are well suited for being able to deliver economical, like-for-like replacement bushing designs. The benefits of RIF® bushings over other bushing technologies were summarized in an earlier blog article. Over the years RHM International has provided hundreds of like-for-like replacement bushing designs from 230 kV to 15 kV for many vintage OIP bushing designs from various manufacturers such as CGE, ABB, Trench (COTA designs), Lapp, Passoni & Villa, Micafil, NGK, Canadian Ohio Brass (COB), Canadian Westinghouse Company (CWC).

When designing a replacement bushing the oil end dimensions are the most critical dimensions that need to be met. The air side length can vary somewhat which is usually due to the different top cap geometric dimensions used by the manufacturers. Below are a couple of examples of recent bushing replacement designs we’ve undertaken.

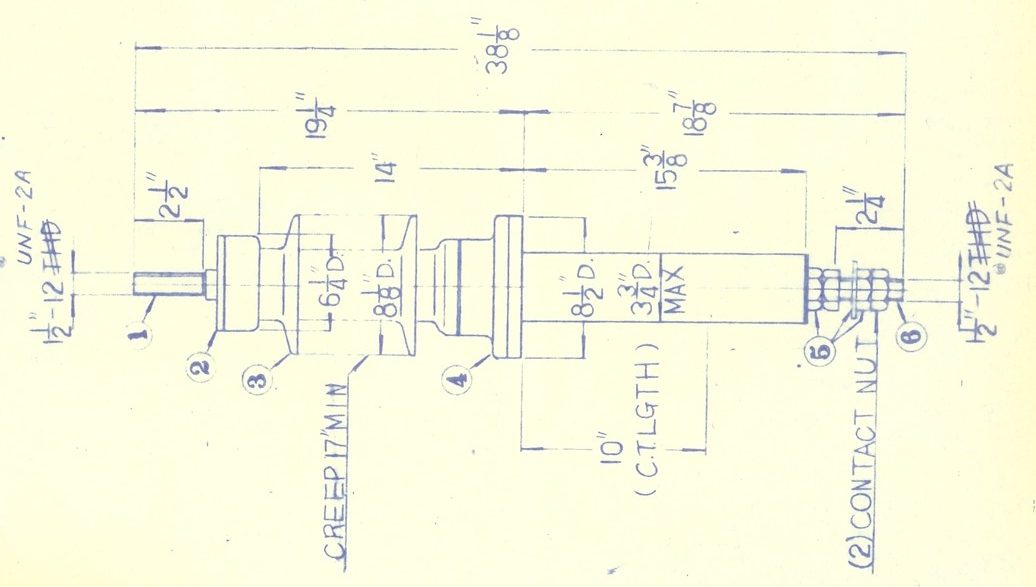

Example # 1 - 1975 Vintage OIP Bushing – 25 kV 1200 A

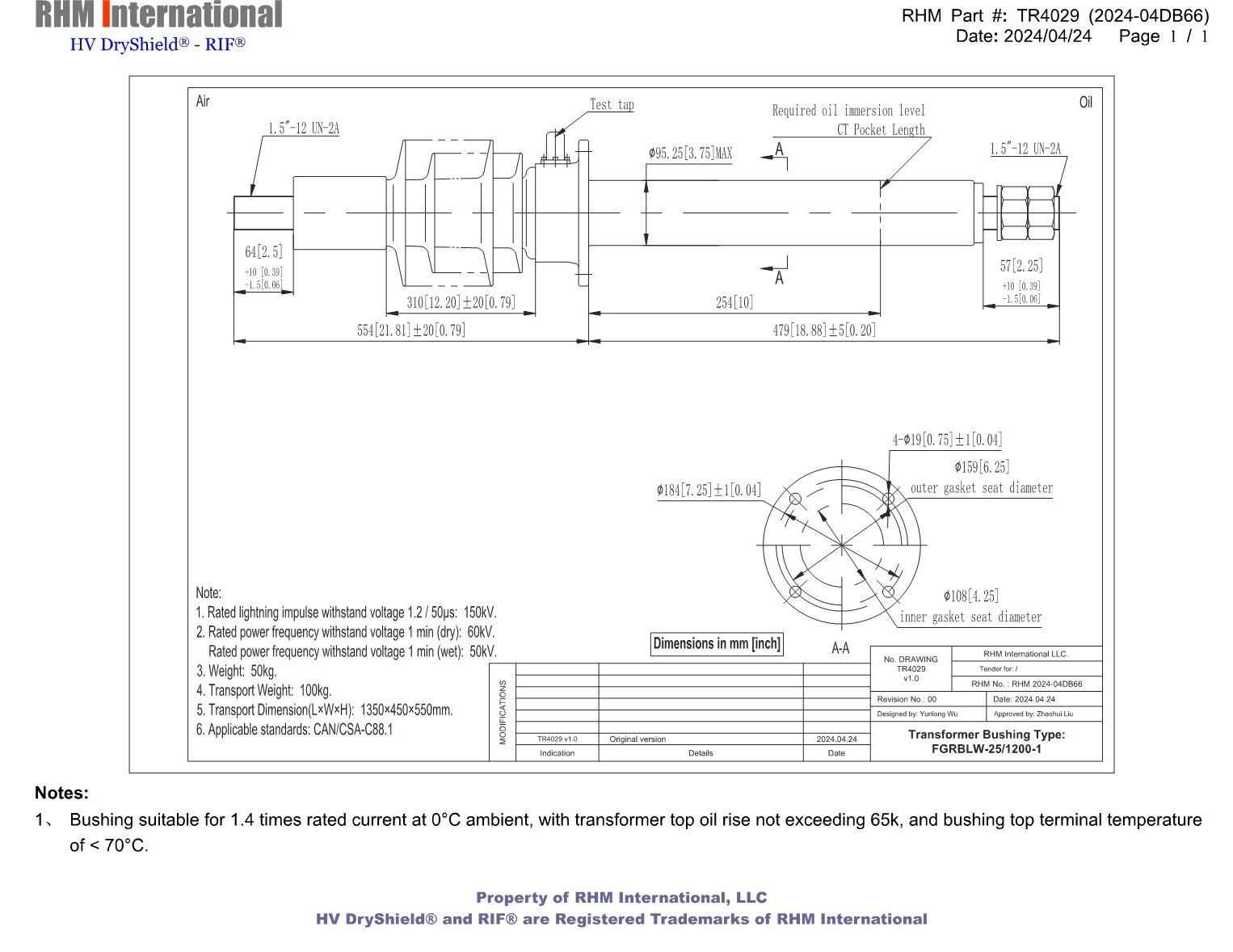

RIF® Bushing Replacement Design

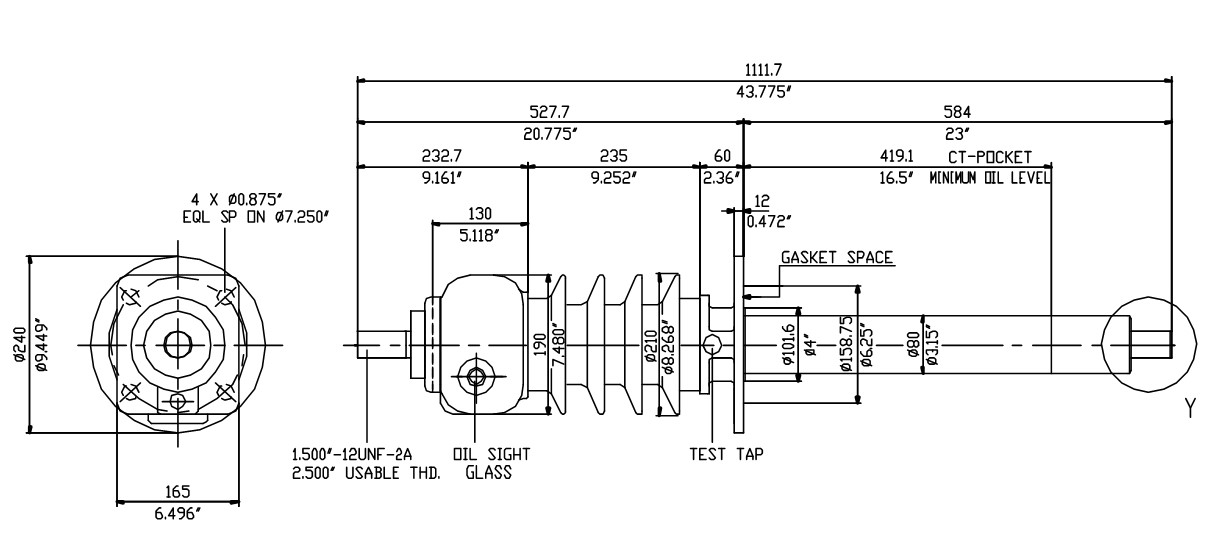

Example # 2 – 1997 Type COTA Bushing – 25 kV 2700 A

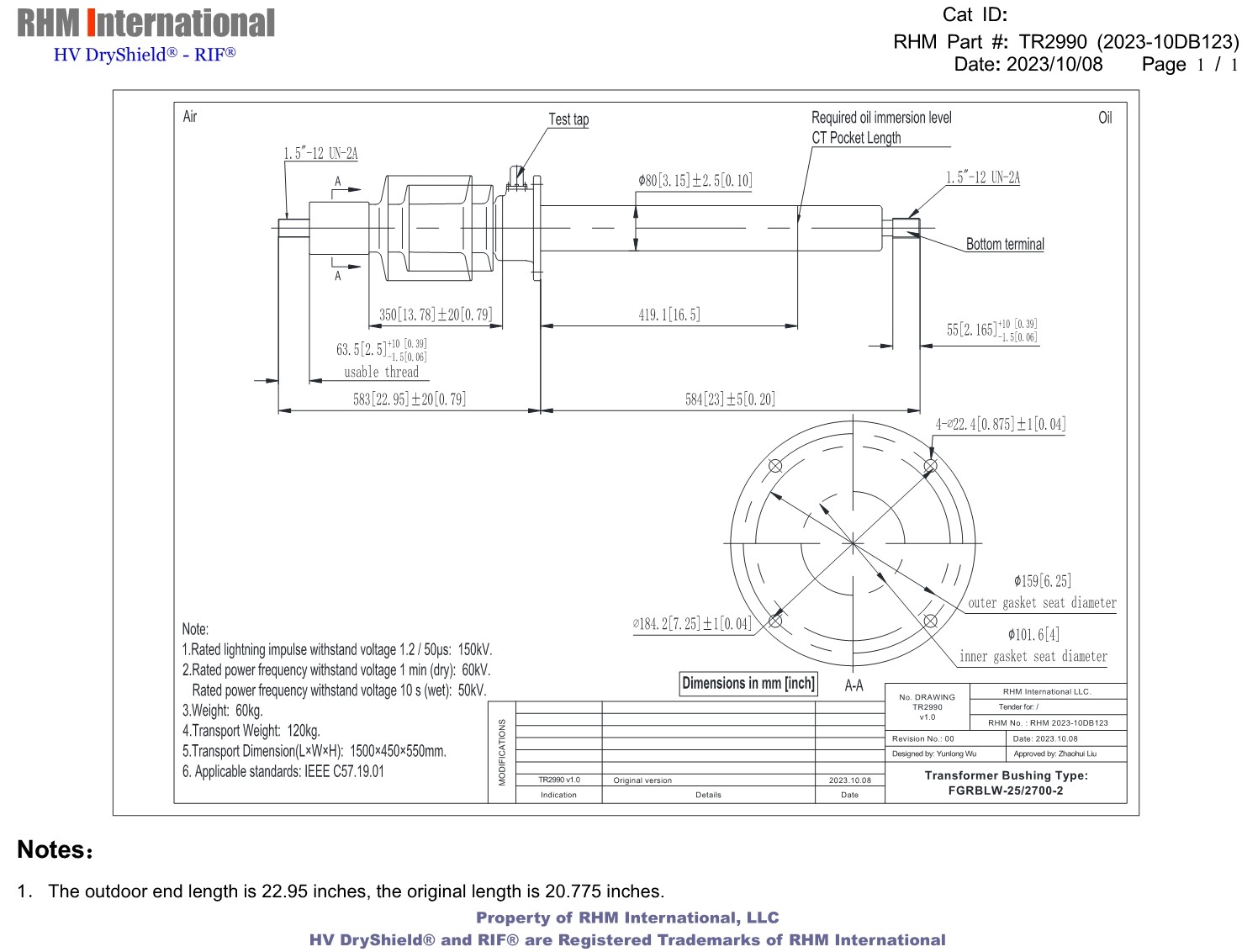

RIF® Bushing Replacement Design

For a design and quote send your request to RHM International along with the dimension drawing(s) of the bushing(s) to be replaced, the quantity required and the delivery address.