There is nothing more frustrating for a customer than to have a piece of equipment leave the factory on time and then experience delivery delays and/or shipping damage. In many cases this is due to an inadequate transportation and logistics planning system that operates in a vacuum and only reacts when the equipment fails to arrive on schedule. These unplanned delays can have significant financial and operating impacts for the customer as capital projects to improve system reliability can get delayed. Some customer specifications will just cover transportation requirements with a simple generic statement like “The Supplier shall design and prepare the equipment for shipment in such a manner that it is protected from damage in transit” while other specifications have very detailed requirements for transportation that include detailed route selection plans and survey reports, permitting requirements, transportation equipment details, risk identification and contingency measures in place, packaging requirements, etc.

In fact, the electrical power industry has recognized the ongoing issue with transportation damage with IEEE and CIGRE both publishing transportation guides for large electrical equipment like power transformers and reactors (IEEE C57.150 and CIGRE TB 673). However, all the guides and specifications in the world can do very little if the supplier is not committed to providing a well-managed transportation and logistics planning system that is proactive and responsive to its customers’ needs. RHM International prides itself on its transportation and logistics planning system which over the years has a less than 0.5% damage rate and 95% on time delivery. To achieve these remarkable numbers RHM International has committed to:

- Maintaining the very successful and long-time relationship with our cargo agents and freight forwarders who have over 40 years of experience in international freight forwarding and are a member of World Cargo Alliance that boasts a membership of more than 6500 members in 235 countries. This company shares the same values as RHM International for reactivity and flexibility and has successfully managed and monitored our transit requirements for over 10 years.

- A customer services program that provides continuous order tracking during production and transit and 2-day response times to customer requests for additional information, technical clarifications and field-installation questions. Our customers are sent shipping notifications and regular transit updates including customs clearance dates and final arrival date at the customer’s facility. RHM International understands that timely communication is a key part of the shipping process when the end customer is planning for a scheduled installation that can involve large budgets.

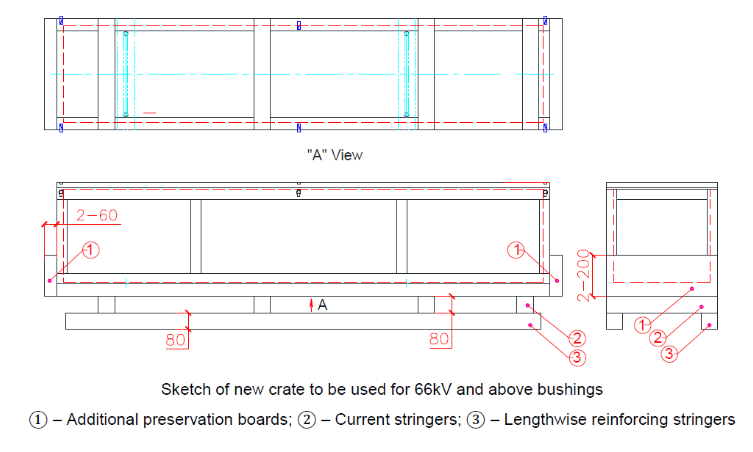

- A continuous improvement loop that will react and adapt to feedback received on the performance of the shipping program and implement lessons learned. For example, a quality assurance program that responds to customer issued Non-Conformance Reports (NCRs) within 2 weeks of the reported problem. NCRs are investigated and resolved using our internal 8D report investigation process. An example of such an 8D investigation related to a transportation issue was a customer report of shipping crates that had sustained forklift damage. Our investigation discovered that the damage had occurred during the container loading and /or unloading process which required the crates to be lifted from their ends. As crates are designed and reinforced to be lifted from the side the lifting of the crates from the ends had resulted in crate damage to the ends. The 8D investigation and resolution process recognized that this would be an ongoing issue with our container shipments and recommended a new crate design for our bushings that would allow both side and end lifting of the crates.