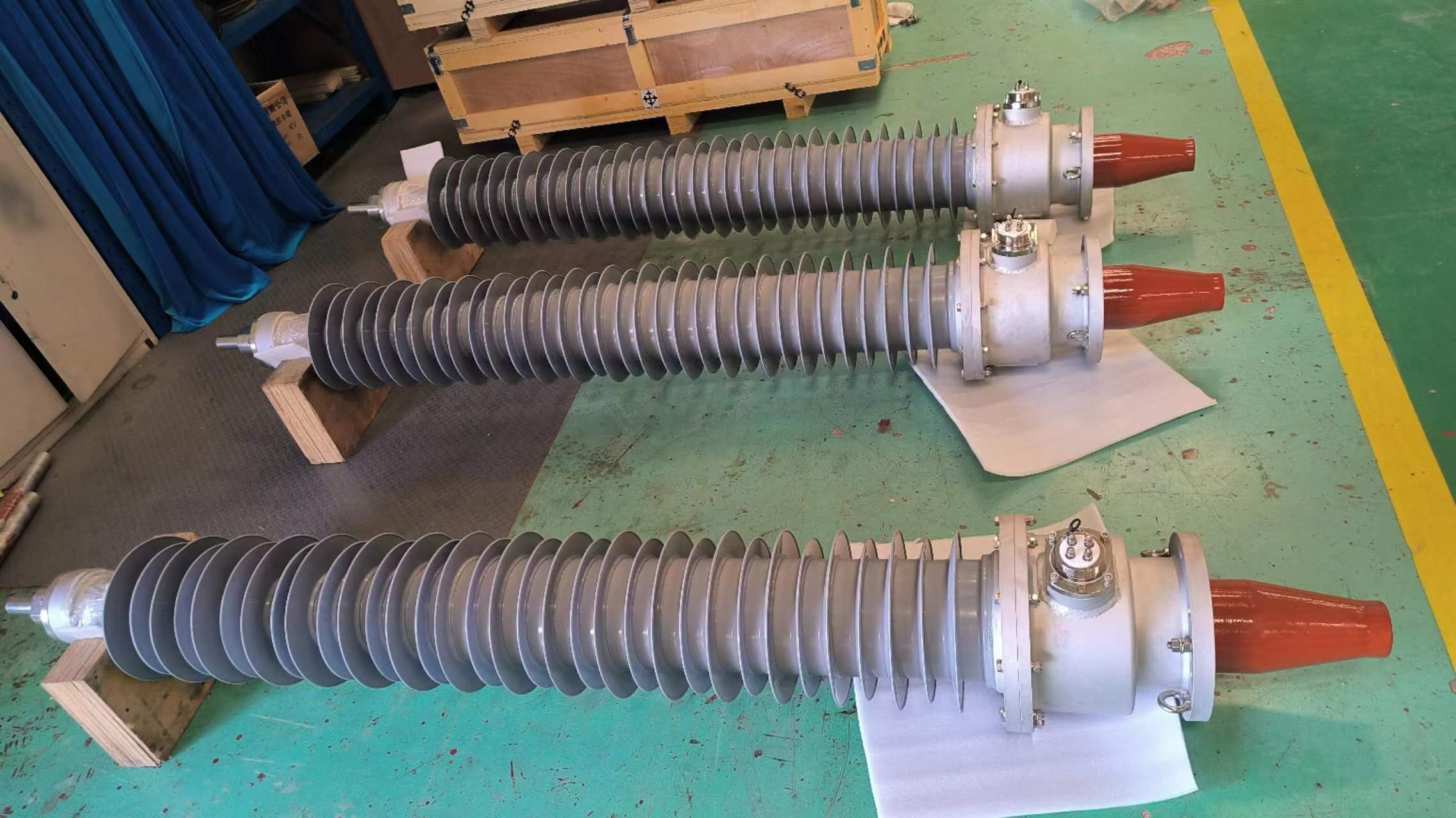

BIIT™ Bushings Lined Up Outside the HV Test Lab

In late 2023 the first BIIT™ bushings will be delivered to a large state-owned utility in Europe. These bushings were ordered with the following technical parameters:

- Maximum voltage of equipment:170 kV

- Rated Line to ground:98 kV

- Rated frequency:50Hz

- Rated Current Ir:1600 A

- Rated lightning impulse withstand voltage 1.2 / 50μs:550 kV

- Rated power frequency withstand voltage 1 min.(dry/wet):260/230 kV

- Rated short time current:40kA, 2s

- Power source:DC 220V/0.1A

- Accuracy class of instrument transformer:Voltage:0.2/3P, Current:0.2S/5P/5P

- Rated secondary output (Metering/Protective): Voltage 2D41H/2D41H, Current 2D41H/01CFH

These bushings will replace the OEM supplied high-voltage bushings on a 170 kV transformer as the utility studies moving away from hardware-based systems in substations to digitally enabled substations.

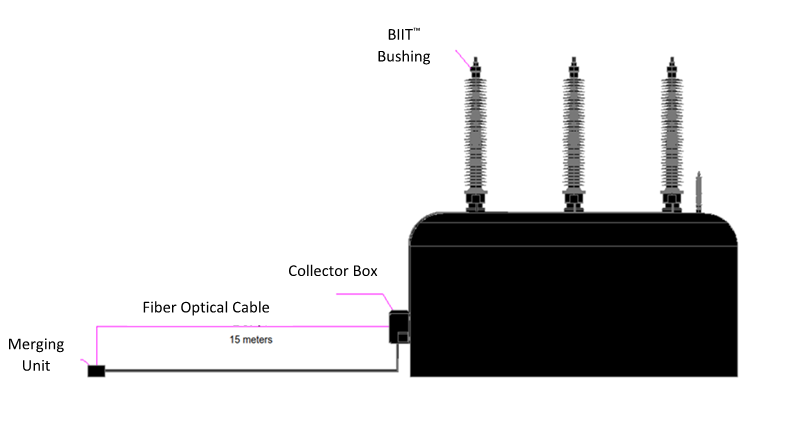

Principles and Key Technologies of the BIIT™ Bushing

The BIIT™ bushing is a new type of solid insulation RIF® bushing with integrated low-power instrument transformers that uses a ground potential platform for its sensing, collector, and converter functions. This device meets IEC 60044-7/8 and follows the IEC 61850 communication protocols to achieve seamless connection with the smart grid.

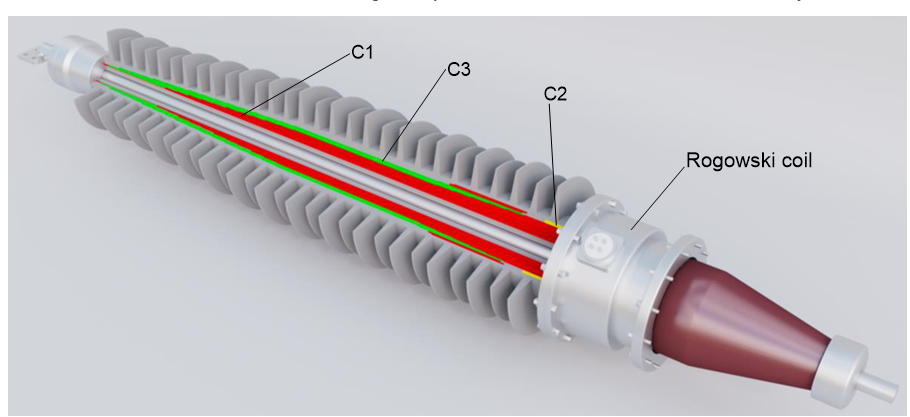

The BIIT™ bushing uses a unique dry type capacitance graded high-voltage bushing insulation structure with three sets of capacitive screens as a primary winding: C1 is a voltage-grading capacitor group for high-voltage insulation, C2 is a voltage-dividing capacitor group made according to the design requirements, and C3 is a shielded capacitor group designed for interference immunity. Using this capacitive design, a voltage signal source with a simple structure, strong stability and a high precision level can be obtained.

The Rogowski coil is a secondary winding, and the secondary winding is placed at the ground potential portion of the dry high-voltage bushing. The Rogowski coil design used is simple to manufacture and provides good temperature characteristics and high measurement accuracy.

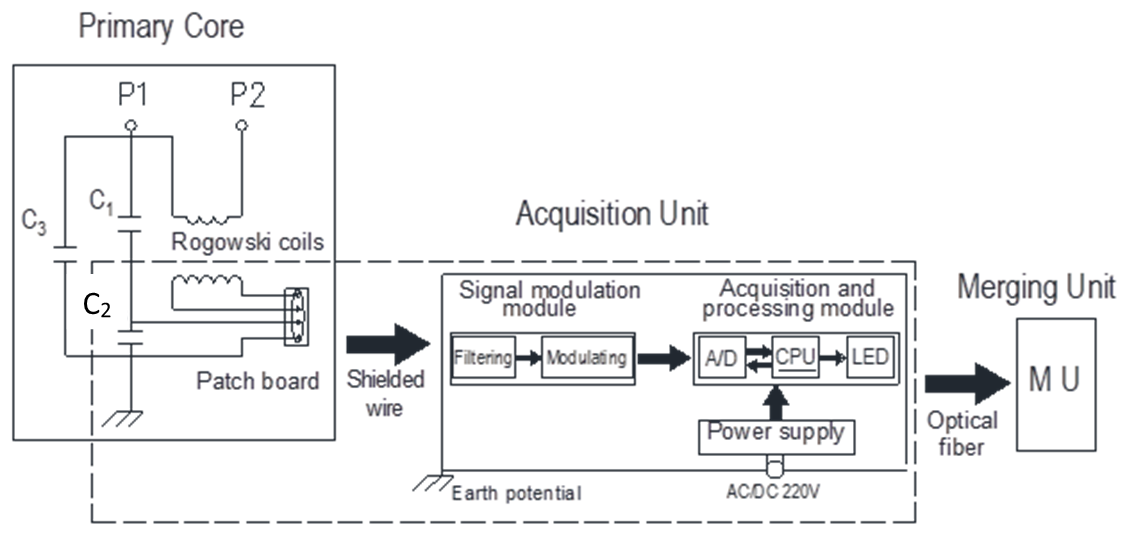

The output signals of the capacitor voltage divider and the Rogowski coil are terminated in the grounded flange column, which effectively solves the problems of the power supply for the acquisition unit, the effects of electromagnetic interference and the off-line requirement for electronic circuit maintenance.

This intelligent integration of capacitive voltage divider and Rogowski coil sensing into one body provides a simple, cost-effective device with a broad range of specifications that is safe to use and easy to maintain.

Cross Section View of the BIIT™ Bushing

BIIT™ Bushing Schematic

Merging Unit Protocols

The merging unit of the BIIT™ bushing adopts the IEC61850-9-2 (LE version) communication protocol, which is a subset of the IEC61850-9-2 standard. Data communication is unidirectional multicast, transmitting from the merging unit to the bay level IED. The default data model is used to configure the working mode of the MU through the ICD file (the ICD file is a template provided by the IED manufacturer that defines the IED’s capabilities). The synchronization mode chosen for this project is the PTP (Precision Time Protocol) IEEE 1588-2019 version.