There has been much talk about future Smart Grids which will rely extensively on substation automation. In traditional substations the connections between devices are hard-wired, which transmits information in the form of analog signals over copper wiring. In the smart substation intelligent electronic devices (IEDs) use Ethernet-based communication to transmit data packets to the network. A new international standard IEC 61850 defines the architecture and transmission protocols used to handle specific types of data transfer. These protocols include:

- MMS (Manufacturing Message Specification) for monitoring the substation status.

- GOOSE (Generic Object Oriented Substation Event) for status updates and command requests.

- SMV (Sampled Measured Values) for transmitting the power line current and voltage values.

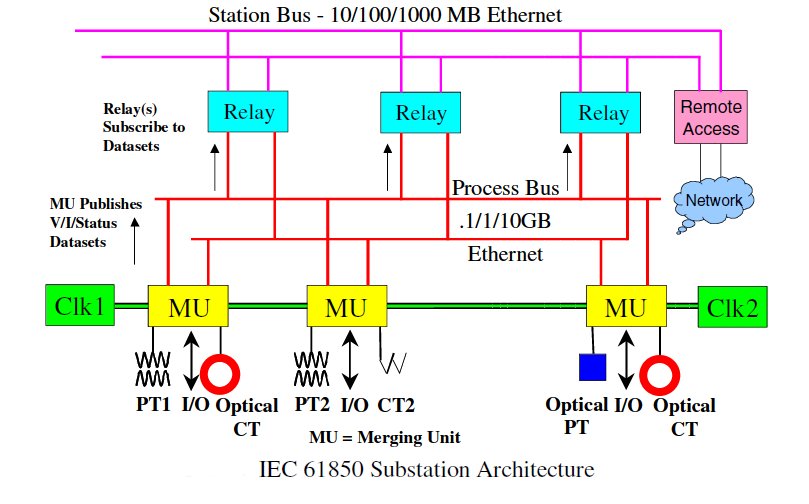

Below is a diagram of the IEC 61850 substation architecture:

The standard divides substation operation into three levels:

- Process level – comprised of devices in different parts of the substation used to measure current, voltage and other parameters.

- Bay level – comprised of IEDs that collect the measurements provided by the process level.

- Station level – this is the level that monitors the status of the substation (this is where you typically find the SCADA, HMIs)

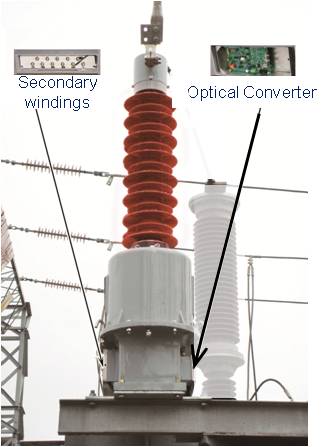

Due to its complexity the IEC 61850 standard will take years if not decades to implement in most countries. In the meantime, CTs that are failing or approaching their end of life will still need to be replaced. For utilities with a focus on a future digital upgrade of their grid a HV DryShield® hybrid CT that is equipped with both traditional secondary iron cores and a Rogowski sensor and its converter has been developed. When the time comes for a substation to be digitally operated a simple switch-over connection in the secondary box is all that is needed to make it a fully operational electronic CT.