In 2018 an internal arcing fault withstand test was conducted on a 245 kV 630 A RIF® bushing. Although the industry standards for bushings currently do not specify such a test requirement RHM International decided to conduct the test in order to validate the explosion-resistant capability of its RIF® bushings. The following test parameters were specified in the test plan:

- Short circuit current = 31.5 kA

- Arc duration = 150 ms

- Asymmetrical peak current = 44.5 kA

Prior to sending the bushing to the test lab a full set of routine tests was done at RHM International’s factory.

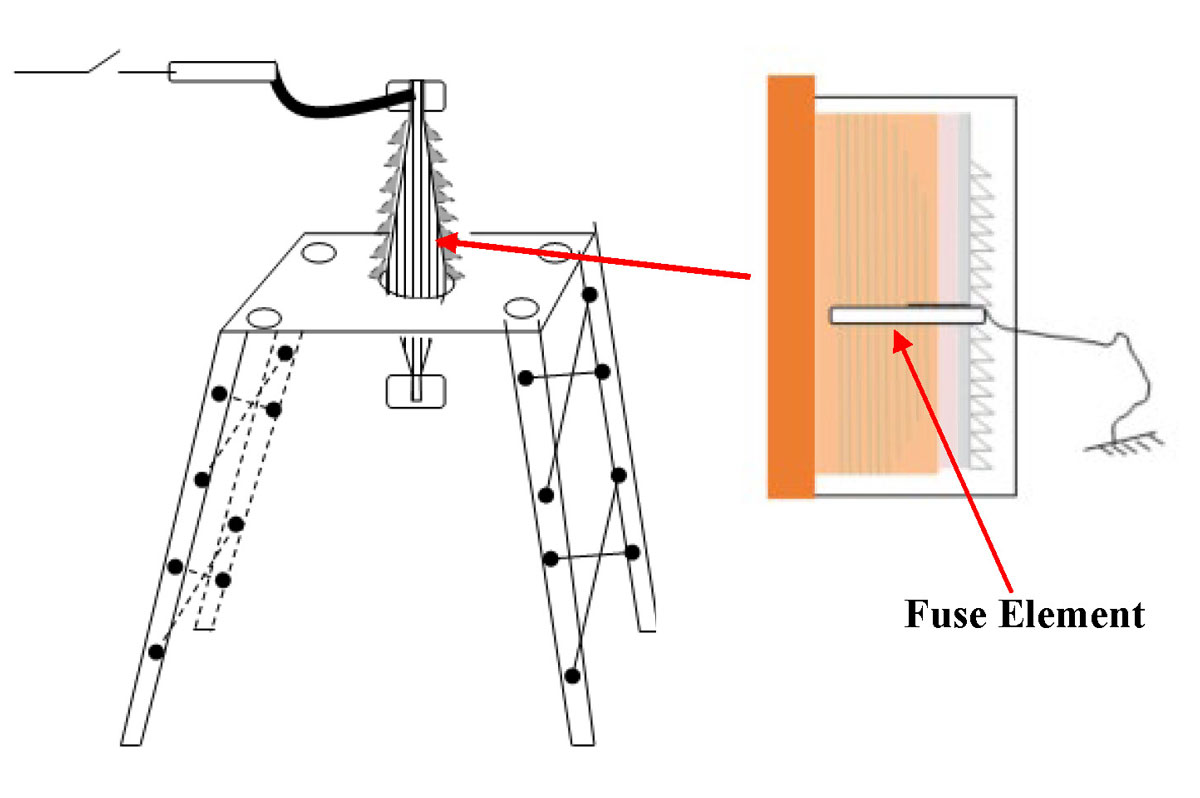

Test Set-Up

The test bushing was assembled on a metal plate which was mounted on an insulated metallic supporting structure. A 2 mm copper wire fuse element was introduced into the bushing on the air side approximately 500 mm from the flange and on the opposite side of the capacitance tap and all the way to the core conductor. The location corresponds to the edge of the last condenser layer, considered the toughest location for the bushing in such tests. The fuse element was grounded at the bushing flange.

Acceptance Criteria for the Test as set by RHM

- The destruction of the upper part (air side) of the bushing is not acceptable.

- No ignition of arc or destruction of the lower part (oil side) of the bushing under the supporting plate is acceptable.

- Sealing shall be preserved between oil side and air side.

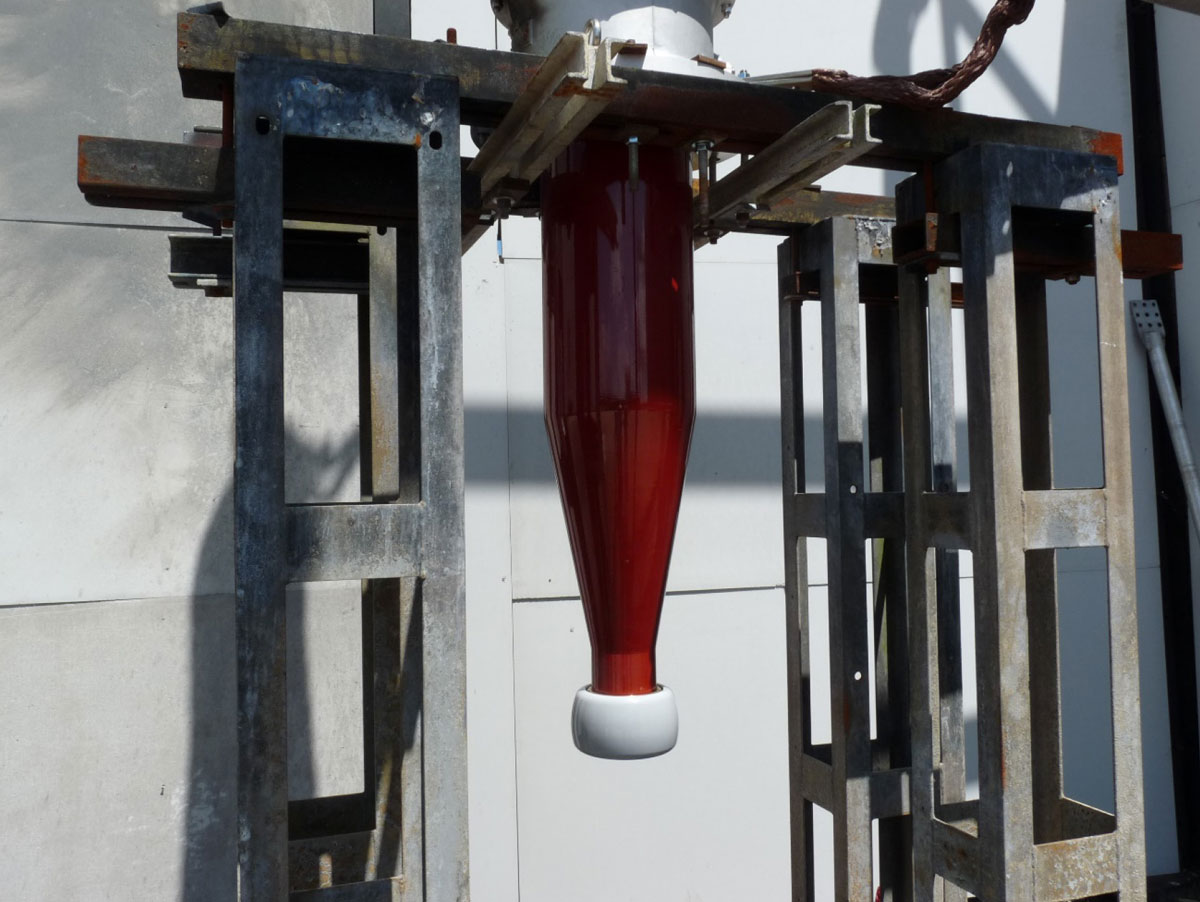

Bushing After the Test

The pictures below show the bushing met all the above criteria. But contrary to what is usually observed with other bushing insulation technologies the RIF® bushing maintained its structural integrity during the internal arcing fault event with no breakage, cracking, mechanical failure or fire being observed. Damage was limited to a puncture at the location where the fuse element was installed. This test validated the explosion-resistant capability of the RIF® bushing and the safety margin of these bushings.

For more information on RHM International's line of Dry Type Paperless RIF Transformer Bushings see the RHM Transformer Bushings product page.

Air End

Oil End

No Structural Damage