As one of the necessary conditions for smart grid development, online monitoring is fundamental to efficient grid management. It can reduce the number and duration of power downtimes for off-line preventive testing, and obtain status of the equipment’s insulation in real time.

But it needs to be reliable and adapt to users resources in handling any type of data generated while providing enough time to investigate and fix any detected issue before major damage can occur to the station.

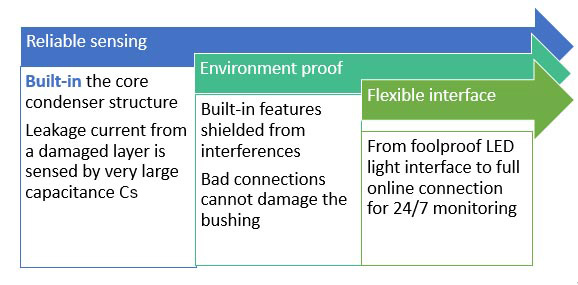

RHM International proposes a unique proprietary built-in environment-proof monitoring with flexible, early fault detection that can be used visually.

The dry type nature of the HV DryShield® and RIF® insulation systems is central in allowing the reliable built-in integration of the LV capacitor Cs and the assurance of stable and accurate monitoring.

The dry, solid nature of our insulation systems translates into a very slow rate of defect propagation through the core structure: early detection provides significant time for investigation and repair of the defect.

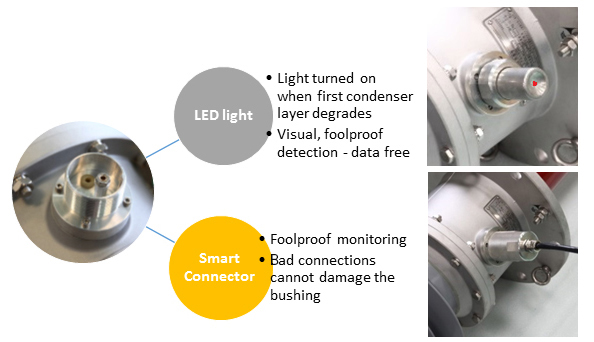

Two interface options are offered: visual or digital.

LED terminal on HV DryShield® Current Transformer

Smart measurement terminal

Advantages of the integrated HV bushing with built-in Cs include:

- Simplicity. The LED light pre-alarm provides users with reliable insulation condition monitoring. This avoids having to manage large quantities of data to identify a growing issue with the core C1 insulation. Maintenance crews just check if the light is on

- Time to act. The LED light provides notification of an early defect. But it will take weeks, if not months to propagate – this is a unique property of our solid dry type insulation. No emergency de-energization of the equipment is required

- Accuracy. The benefit of using a capacitive voltage divider with its higher interference shielding capability and better accuracy versus the approach of using current sensors made of iron core coils

- Reliability. Keeping the C1 and Cs connections inside the integrated capacitance-graded insulation core; this connection will not open, and the last screen lead is reliably grounded

- Safety. The external monitoring and data acquisition device will not affect the high voltage insulation, even in the event of damages due to operational mistakes such as short circuit or open circuit

- Consistency. Since the material and workmanship of C1 and Cs are the same, there will be no large errors due to changes of temperature or frequency assuring consistent monitoring accuracy

- Self-Powered. Power for the monitoring device is supplied from the grid. Therefore an external power source is not needed, avoiding expensive installation.