Cascade_RIF® EHV Bushings – 362 kV and above

When designed for EHV applications core insulations become quite large, stressing manufacturing yields, lead times and costs. RHM International is addressing this challenge with an innovative approach: the Cascade_RIF®.

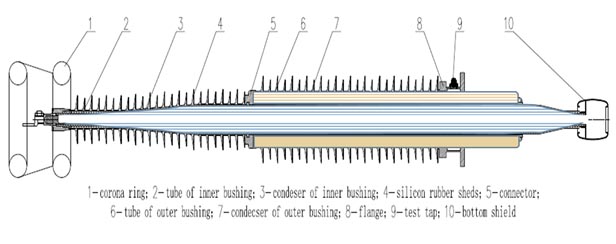

The bushing uses our well proven proprietary multilayered resin impregnated fiberglass RIF® material system for the condenser core insulation and a high quality silicone rubber outer insulation envelope.

The Cascade design splits the core insulation into a series of condenser graded substructures, each of which carries a fraction of the maximum system voltage. The advantage of this design approach is that it allows each substructure to be manufactured using the same proven production processes of lower voltage bushings thereby reducing the lead times and manufacturing costs for EHV bushings.

In addition to a stable insulation structure each section (substructure) has a metal tube which helps with heat dissipation and the temperature rise performance.

362 kV Cascade_RIF® Transformer Bushing

Sectional View of 362 kV Cascade_RIF Bushing

Benefits of the Cascade Design:

- Lower manufacturing costs and shorter lead times.

- Higher reliability due to a better heat dissipation design and reduced insulation volumes which allows for better control of the internal stresses during manufacturing.