The HV DryShield® line of CTs can be designed to meet the specific requirements of customer specifications including full compliance with all types of international standards (IEC, IEEE, CAN/CSA, etc.). The internal and external insulation materials used in the HV DryShield® type LRGBJ current transformer design provides a piece of equipment that is safe and reliable in all types of operating environments including exposure to extreme ambient temperatures (-50°C to +50°C), marine climates, industrial pollution and High Level seismic activity.

The HV DryShield® line of dry type current transformers can be supplied with the following operating and insulation ratings:

(i) Rated voltage: 72.5 kV up to 800 kV

(ii) Rated frequency: 50Hz and 60Hz

(iii) Rated primary currents: 1 – 5000A

(iv) Rated short-time thermal current: up to 72kA

(v) Rated dynamic current: up to 180kA

(vi) Rated secondary currents: 5A or 1A

(vii) Rated outputs: 2.5 – 50VA

(viii) Rated burdens: B0.1 – B8

(ix) Metering accuracy classes: 0.1, 0.15, 0.15s, 0.2, 0.2s, 0.3, 0.5, 0.5s, 0.6, 1.0, 1.2, 3, 5

(x) Relaying accuracy classes: 5P, 10P, PX, TPY, 2.5L, 10L

(xi) Temperature-rise limit: class B (85K)

(xii) Rated insulation levels (LI/SI/PFW•60s) for primary windings: up to 2100/1550/975 kV

(xiii) Partial discharge level: no more than 5pC at 1.5Um/√3 kV

(xiv) Capacitance and dielectric dissipation factor: less than 0.004 at 10 to Um/√3 kV

(xv) Test tap insulation: 5 kV (r.m.s.)

(xvi) Between-section insulation: 3 kV (r.m.s.)

(xvii) Secondary windings insulation: 3 kV (r.m.s.)

(xviii) Inter-turn insulation: 4.5kV (peak)

(xix) Radio Interference Voltage (RIV) and Transmitted overvoltage: meets all Standards requirements (IEC, IEEE, CAN/CSA, etc.)

(xx) External insulation creepage: meets all Standards requirements (IEC, IEEE, CAN/CSA, etc.)

(xxi) Static loads: meets all Standards requirements (IEC, IEEE, CAN/CSA, etc.)

(xxii) Seismic performance: IEEE 693 HIGH LEVEL

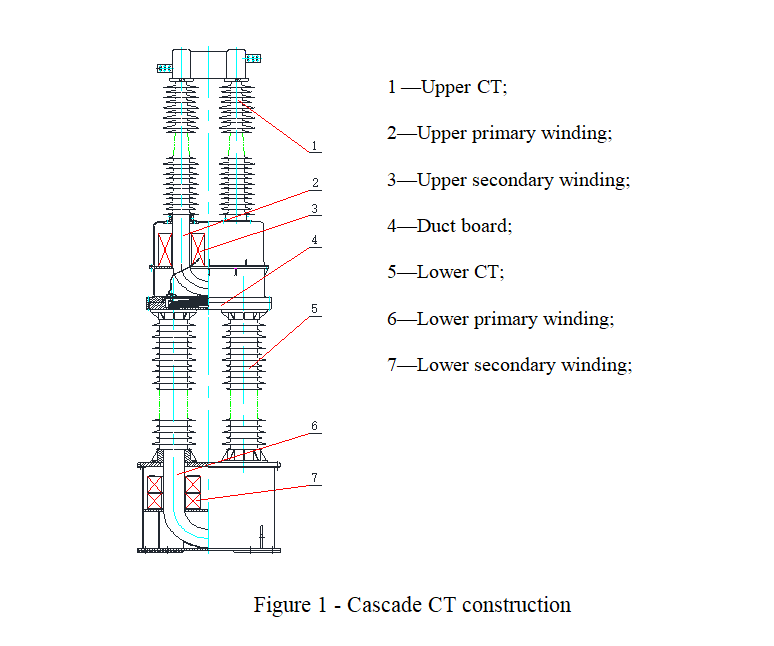

EHV ratings (>500 kV) are attained with the cascade style HV DryShield® type LRGBJ current transformer (see Figure 1). The cascade design utilizes two lower voltage CTs connected in series. The primary winding of the upper CT is connected to the grid and is at high potential. The upper CT primary’s last layer, secondary winding, casing and duct board are connected with the primary of the lower CT which are at intermediate potential. The secondary winding and casing of the lower CT are at zero potential, i.e. earth potential. The secondary of the upper CT and the primary of the lower CT are in series connection, the secondary winding of the lower CT is connected to an external burden. This type of construction offers the following advantages over conventional post type CTs at EHV levels (beyond the usual dry type related advantages of HV DryShield®):