RHM International was one of the 920 industry exhibitors at the 2018 IEEE PES T&D Conference and Exposition held in Denver, Colorado from April 16th -19th. This show is one of the premier events for the electrical power industry providing a forum for a wide range of technical topics (e.g. smart equipment, grid resiliency, energy […]

HV DryShield® Electronic Current Transformer – Traditional and IEC 61850 Compatibility in One Hybrid Device – Part 2

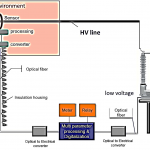

There has been much talk about future Smart Grids which will rely extensively on substation automation. In traditional substations the connections between devices are hard-wired, which transmits information in the form of analog signals over copper wiring. In the smart substation intelligent electronic devices (IEDs) use Ethernet-based communication to transmit data packets to the network. […]

HV DryShield Electronic Current Transformer With Rogowski Coil Current Sensing – Part 1

Using the robust and proven HV DryShield® insulation technology combined with a Rogowski coil sensor the evolution to a digital operation current transformer (CT) was a straightforward process. The HV DryShield® electronic CT uses a dead tank design that houses the sensor and primary converter in a grounded box which provides shielding from electromagnetic interference, […]

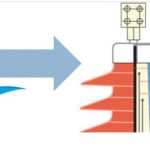

Grading Condenser and Uniform Field Design of the HV DryShield Current Transformer

The HV DryShield® line of CTs has been designed for a very long component and operating life. To achieve this the design looks at achieving optimum performance in three specific areas: A Low Dielectric Loss for the Main Insulation Material The tanδ of the insulation material is very important to the design. Too high a […]

Ratings and Service Conditions of HV Dry Type Current Transformers

The HV DryShield® line of CTs can be designed to meet the specific requirements of customer specifications including full compliance with all types of international standards (IEC, IEEE, CAN/CSA, etc.). The internal and external insulation materials used in the HV DryShield® type LRGBJ current transformer design provides a piece of equipment that is safe and […]

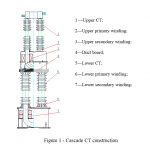

Structure, Insulation and Characteristics of HV Dry Type Current Transformers

The next series of articles in our blog will review the history and development of HV dry type current transformers (CTs); and in particular the line of dry type current transformers that was developed in the 1980’s and later patented in the 1990’s and trademarked as HV DryShield®. For decades utilities have been seeking to […]

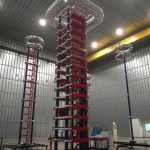

Equipment Testing Capabilities of the RHM High Voltage Laboratory in New Hampshire

In this month’s article the testing capabilities of RHM International’s new High Voltage Test Laboratory are discussed in more detail. The main purpose of the lab is to provide routine testing for RHM International’s manufactured products (bushings, current transformers, cable terminations) with nominal voltages up to 500-600kV. The lab also can perform high-voltage insulation tests […]

RHM International is opening of a new North American Production and Test site in Hudson, NH

RHM International is ramping up its production readiness with a new North American site that included an 18 month construction installation project of a new high voltage testing laboratory (see blog for description of the endeavor). This is the first site in North America for the company which is designed to bring its innovative dry […]

New RHM International HV Testing Laboratory in New Hampshire

For Routine & QA Testing of MV, HV and EHV Dry Type Bushings, Current Transformers and Cable Terminations RHM International’s marketing plans required expansion of their product manufacturing facilities outside of China. As a first step in this plan a new manufacturing plant to serve the North American and European markets was constructed in the […]

Transformer Bushing Standards

In North America the three main bushing standards that are used are CAN CSA C88.1, IEEE C57.19.00/C57.19.01 and IEC60137. The CSA standard is in large part an adoption of the IEEE standard with some specific Canadian requirements (e.g. operational capability at -50°C is seen more as a standard requirement than a special requirement). However dimensional […]